Long-haul trucking depends on the normal operation of vehicles, which is why they are always under mechanical stress. The driving with more hours on average, loading goods on different weight scales, the exposure to the weather, and only a fast recovery time between trips are the clarifying factors leading to the dominant error of mismanagement. Thus, the things that can go wrong even with a truck on a short distance run that are difficult to manage for drivers become a serious issue later on. Not about getting back to norm faster; instead, it is about the structure of the system built that is responsible for the protection from the unwanted accidents even before the wheels turn.

The majority of the long-distance service vehicles that fail do not occur on a random basis. They are the culmination of a period where inspections were missed, service intervals were stretched, and drivers did not keep to their routines consistently. The most problem-free way to deal with this issue is through a system that is established by strict interval disciplines, rigorous inspections, and maintenance routines. This structured process will, with time, turn your vehicle into a reliable machine that will avoid roadside repairs, savings on expensive repairs, and ultimately, extend the vehicle life span.

A structured maintenance procedure is the most reliable approach to preventing breakdowns before small issues escalate into route-ending failures.

This article will provide a practical, step-by-step technique to long-haul breakdown prevention that can be applied at the driver and fleet management levels.

Why Long-Haul Operations Are More Prone to Breakdowns

Long trips amplify small mechanical problems. For example, a small imbalance of coolant, a gradual degradation of oil, or an early failure of lubrication may go unnoticed during short runs, but become critical after hundreds or thousands of miles.

On long trips, small mechanical deviations tend to compound over distance rather than resolve on their own.

The deeper operational issues are in the key risk factors:

- constant engine load for far more time

- lack of opportunities to repair mid-route

- weak heat stress on important parts

- delayed brief exposure for repairs

A vehicle breaking down when it is miles away from a service point becomes a nightmare for both cost and operational ability.

Roadside breakdowns often represent the final stage of issues that were detectable well before departure.

This means that prevention should be implemented precursively.

Preventive Maintenance: A System, Not Just a Task

Preventive maintenance is usually considered to be a checklist item rather than a procedure. In reality, it is a system consisting of regular intervals, inspection rules, and clarification of roles. Proactive preventive maintenance programs that follow structured intervals and scheduled servicing have been shown to reduce mechanical failures, improve fuel efficiency, and reduce downtime for heavy-duty truck fleets. multiservicefuelcar

The purpose of effective preventive maintenance:

- decrease the risk of sudden breakdowns

- prolong the life of vehicles

- botllow stabilize the operating costs

- increase safety and on time performance in schedule

Since this system supports predictability, it is a plus for fleets. It is also a plus for drivers on long hauls, giving them clarity and confidence.

Is YOUR Truck Ready for the Long Haul? Our Preventative Maintenance Service Ensures It Is

Maintenance Intervals: Timing As The First Shield

Preventative Maintenance for Large Trucks

Maintenance intervals are there to make sure that the components do not neet the threshold failure. Stretched deadlines seem shorter in the beginning, but that is not the case in the end, which makes such practices the most dangerous because then you are almost doubling the chance of breakdowns on long-haul routes.

Long-haul maintenance is usually related to some critical intervals such as:

- oil and filter changes

- transmission check

- coolant inspections

- lubrication points

- brake system wear

Heavy haul maintenance requires closer attention to load-related stress, as sustained weight accelerates wear on multiple systems simultaneously.

The primary reason for the intervals which are not on the base of the schedule is to reduce server troubles, that is why intervals need to be based on mileage, operating hours, and actual loads instead of the convenient route. Extreme climate or high cargo routes could make it necessary for some vehicles to be serviced more often than stated in the standard guidelines.

Key Maintenance Intervals for Long-Haul Trucks

| Component | Inspection Frequency | Purpose |

| Engine Oil | Scheduled mileage intervals | Prevent engine wear |

| Transmission | Regular service checks | Detect early gear stress |

| Coolant system | Pre-trip and service intervals | Avoid overheating |

| Lubrication points | Scheduled maintenance | Prevent friction failures |

| Brakes | Routine inspections | Maintain stopping safety |

Inspection Discipline: Where Breakdowns Are Actually Prevented

Inspection discipline is the parameter that differentiates the fleet that reacts only to breakdowns from those that actually prevent them. Only when pre and periodic inspections are performed seriously will the maintenance checklist be effective.

It is wrong for the truck inspection to be treated as a memorized routine or a quickie. A pre-trip inspection, especially, takes a big part in successful performance through the year.

Among the very important inspection spots are:

- fluid inspections for leaks or abnormal levels

- engine oil condition and consumption trends

- transmission behavior during gear shifts

- coolant system pressure and temperature stability

- visible signs of lubrication failures

Inspection discipline implies doing the same checks for each vehicle every time, regardless of the schedule pressure.

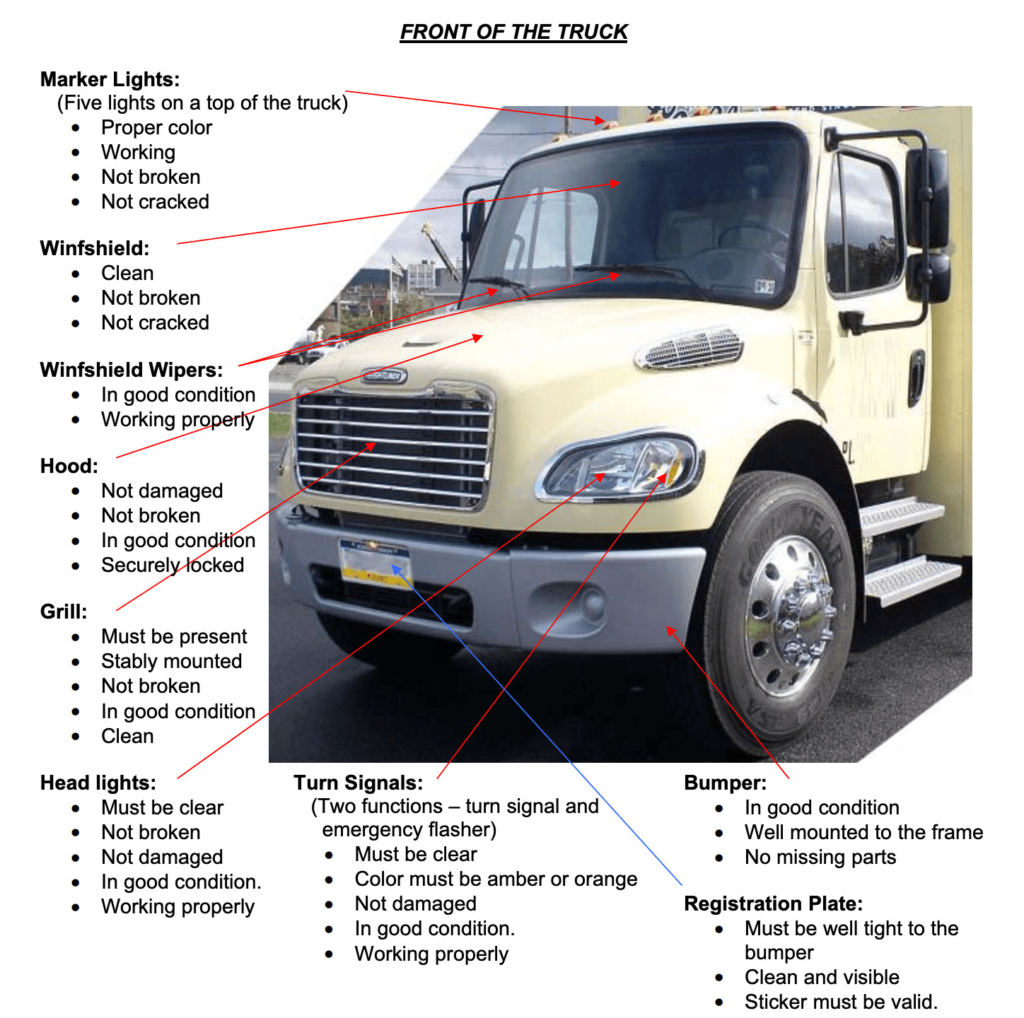

Pre-Trip Inspection: The Only Chance to Avoid Breaking Down

Pre-trip inspections focus on critical components whose failure would immediately disrupt the route.

Pre-trip inspection is the last control check for the vehicle before it starts a long journey. During the journey, there are hardly any corrective measures one can take.

An organized pre-trip inspection concerns with critical parts instead of decoration issues. Instead of looking for perfection, drivers should look for changes.

Common pre-trip inspection failures that lead to breakdowns include:

- ignoring small fluid leaks

- overlooking gradual oil consumption

- dismissing minor warning indicators

- assuming previous trip performance guarantees current readiness

Driver discipline in pre-trip inspection directly affects the rate of breakdown prevention.

Fluid Inspections: Small Deviations, Big Consequences

Fluid systems are among the most failure-sensitive areas in long-haul trucking. Engine oil, transmission fluid, and coolant operate under constant thermal and mechanical stress. Regular coolant checks help identify early thermal imbalance before overheating becomes unavoidable.

Fluid inspections should focus on:

- level consistency

- contamination signs

- abnormal consumption patterns

Lubrication failures are not likely to occur all of a sudden. They manifest through gradual deterioration, which is why fluid checks are one of the most productive methods of preventive maintenance.

Often, the repair costs that result from fluid problems are not only unavoidable but also high and hence, they could have been avoided by regular checks.

Maintenance Schedule Compliance and Fleet Management

From the fleet management perspective, complying with the maintenance schedule is a way to reduce costs. Vehicles that are regularly maintained have fewer breakdowns and run for longer.

Preventive maintenance fleet level requiries:

- standardized service guides

- proper maintenance records

- clear responsibilities between drivers and maintenance personnel

Service guidelines exist to define safe operating limits and should not be treated as flexible recommendations.Once maintenance schedules are perceived as variable, the risk of the breakdown during long-haul operation increases exponentially.

Driver Discipline: The Human Factor in Breakdown Prevention

Driver discipline determines whether inspection procedures are followed consistently or reduced to a formality. Even the most meticulously planned maintenance schedule will not succeed without driving discipline. Drivers are the first to notice and report the problems.

Driver discipline entails:

- reporting the early warning signs as soon as possible

- adhering to the inspections

- avoiding compensatory driving behaviors during the issues

- following the service instructions

One of the chief causes of the avoidable breakdowns is the negative behavior of the driver. Training and reinforcement are part of the solution.

Preventive Maintenance vs Roadside Breakdown Impact

| Factor | Preventive Maintenance | Roadside Breakdown |

| Cost | Planned and predictable | High and variable |

| Safety risk | Controlled | Elevated |

| Downtime | Minimal | Extended |

| Vehicle life | Extended | Reduced |

| Schedule reliability | Stable | Disrupted |

Long-Term Impact: Vehicle Life and Cost Control

The process of keeping the long-haul truck breakdowns away from the track is mostly about avoiding the immediate concern. It affects the vehicle’s life and overall cost of ownership in a direct way.

Regular vehicle maintenance:

- lowers the amount of wear

- will keep the performance steady

- decreases the frequency of major repairs

- gives more predictable asset utilization

As a result of ignoring the small issues, which are the basis of the problem looking for the solution to the one-time costs, the repairs become expensive. Preventive maintenance serves to protect both the equipment and the operating budget.

Final Thoughts: Discipline is the Procedure

There is not a single action that can fully prevent long-haul breakdowns. The procedure, on the other hand, is built by the intervals being respected, the inspections being consistent, and the discipline that gets enforced every day.

Preventing breakdowns is a matter of reacting faster—no; it is about not ignoring the little signals. Long-haul trucking has discipline not so much in completing the route as in stopping on the shoulder.

The checklist structure of maintenance, together with inspection discipline and driver accountability as its backbone, continues to be the most reliable way to assure the trucks stay on the road while operations function without a hitch.

FAQ

What is the main reason for long-haul breakdowns?

The majority of the long-term breakdowns are not sudden mechanical failures. Most of them are caused by late maintenance intervals, insufficient inspections, or gradual wear that went undetected. The omission of small irregularities like fluid levels, temperature, or component behavior will usually lead to roadside breakdowns further along the route.

When should long-haul trucks be inspected?

The frequency of inspections should not be based solely on fixed dates; it should be determined by mileage, operating hours, and load conditions. Before each long trip, the pre-trip inspection is mandatory, while the deeper inspection should follow the regular maintenance schedule specified in the service guidelines and actual truck usage.

What is pre-trip inspection necessity for the long trips?

The pre-trip inspection is actually the last chance to discover any problems before a vehicle is on a long route that is virtually impossible to be repaired. At this stage, small fluid leaks, early lubrication failures, or abnormal engine behavior can prevent the problems and make it expensive to repair or more extended downtime.

Which components are of utmost importance during the long-haul operations?

The critical components include the engine oil systems, transmission components, coolant systems, lubrication points, and brakes. These components are under continuous stress during the long journey, and even the slightest deviation if untreated can manifest as a serious failure in the near future.

In which way does driver discipline affect the breakdown prevention?

Driver discipline influences the consistency of inspections and the accuracy of reporting directly. The most detailed acid test of a maintenance schedule is, however, rendered useless if the drivers do not listen to the early warning signals they get or procrastinate on reporting the problems. Good habits of inspection and following the service procedures will make it highly unlikely for the truck to experience such a malfunction.

Can it be said that preventive maintenance can really lead to a decrease in operating costs?

Sure. Preventative maintenance keeps the truck off the road for the least time, it decreases the money needed for repair, and it also increases the truck’s speed. Even though it takes time and determination, it assures predictable maintenance expenses instead of high and unexpectedly varying costs that are connected with emergencies.

In what ways does fleet management come in your service breakdown prevention?

The fleet management holds out the guarantee that the maintenance schedules will be observed, the inspection standards will be uniform, and the service records will be kept. Clearly stating the responsibility of the drivers and the maintenance teams will reduce the occurrence of missed inspections and delays related to long-haul repairs.

Are roadside breakdowns always avoidable?

All roadside breakdowns are not preventable, however, most of them can be avoided. The bulk of them are caused by no response to signals, run out of inspection and service intervals. The process of dedicated maintenance can cut the chances of them happening a great deal.