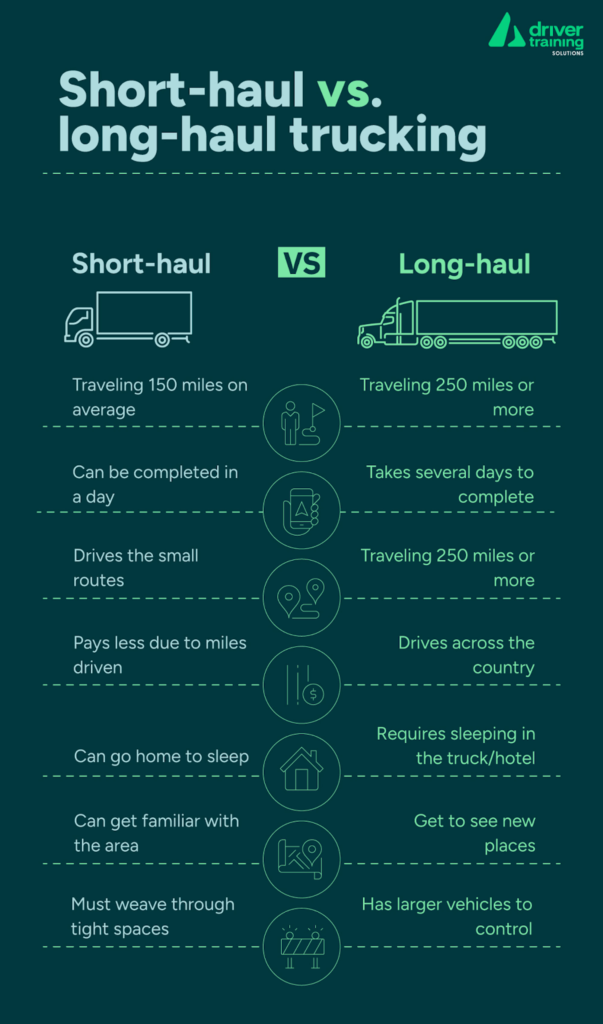

Short-haul trucking is similar to a dance where all the drivers have to be in tune with their schedules. Rapid delivery windows, many stops, frequent starts, dense city traffic, and reduced recovery time between shifts create unique pressure for the semi-truck. Unlike the long-haul distance that reduces the effects of wear and tear, the short ones do not affect the truck differently — instead, they often accelerate it. The daily pre-shift maintenance thus becomes a necessary step to ensure that everything is operational and not just a formality.

A short-haul maintenance checklist that is concise permits the drivers to detect problems in the early stage, observe safety rules, and prevent small malfunctions from transforming into downtime during peak season. This guide covers the pre-work daily checks you need to do, their rationale, and how to eradicate the hurried nature of your inspections by turning them into a norm.

Quick communication on the road prevents mistakes and keeps stress low — especially for rookies. Here’s a practical list of CB slang every driver should know so you don’t miss important messages.

The Importance of Daily Maintenance in Short-Haul Operations

Short-haul trucks are generally utilized more under stop-go situations than long-haul trucks. In other words, this causes the brakes to be cycled day and night, in turn, the engines to cool down and heat up, the air pressure to fluctuate, the electrical systems to be frequently loaded.

The common factors creating the risk in the short-haul are:

- Frequent acceleration and braking

- Higher exposure to curbs, docks, and tight yards

- Frequent engine restarts

- Limited time between shifts

- Urban traffic stress

Because of all these reasons, preventative maintenance is a must-do activity rather than an occasional task that can be done once every so often.

The most proven way to unveil your truck problem is through a daily vehicle inspection that helps to check out the wear on the vehicle before affecting the safety or the delivery schedules.

Every missed inspection today means the probability of a truck breaking down tomorrow — often during busy hours.

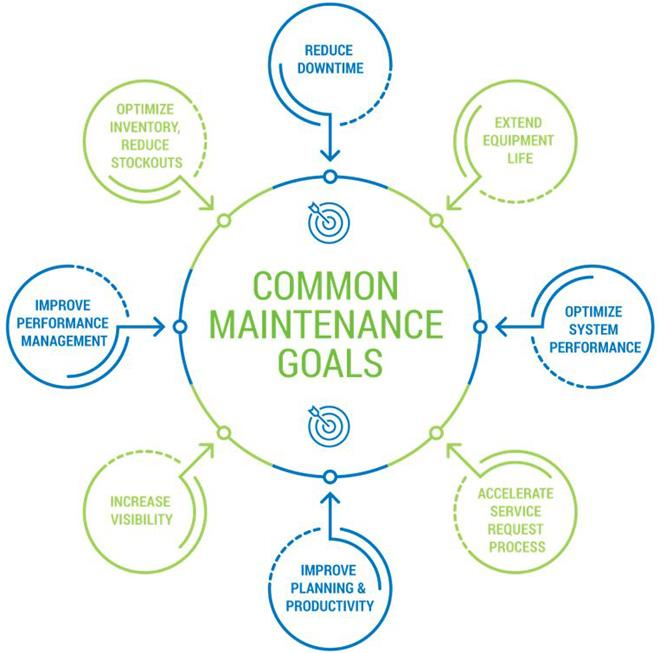

The Aim of the Before-Shift Maintenance Checklist

The daily pre-trip inspection is not aimed at fixing issues at the moment. It highlights operational readiness and allows all risks to be recognized in adequate time to enable safety.

Well-organized daily checklists:

- maintain the truck’s safety and security for use

- catch the wear early

- protect the driver and surrounding people

- provide maintenance logs and service records

- reduce the frequency of unexpected route interruptions

The inspections are not on some inner mechanism fixing jobs. They work as a safety-check channel.

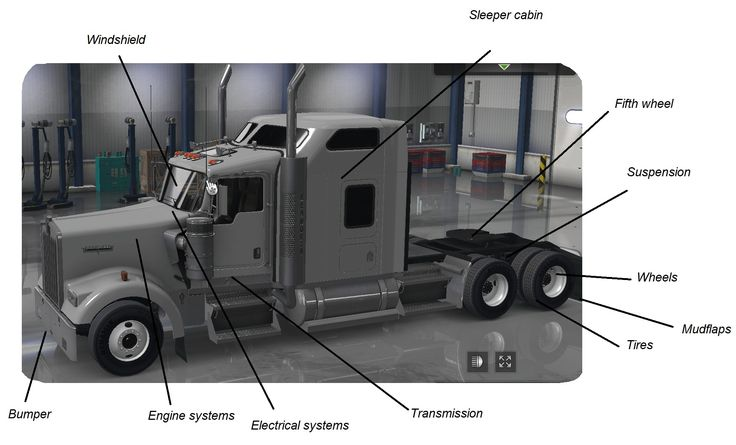

Step 1: Walk-Around Vehicle Inspection

Make a visual walk-around observation the first step. Before you sit at the driver seat, take a look at the exterior of the truck. You will be surprised at how many things you can find just by checking the outside first before getting in the cab.

Look for:

- visible fluid leaks under the truck

- body damage, loose panels, or hanging parts

- condition of mirrors and lights

- properly secured steps, grab handles, and doors

This initial vehicle inspection sets the baseline for all further checks during the shift.

A brief walk-around inspection lays a solid foundation for the subsequent daily checks.

Step 2: Tire Inspection and Air Pressure

Tires take the hardest hit in short-haul service. Continuous turning, contact with curbs, and braking cause early wear.

The following should be included in tire inspection:

- visible damage or bulges

- uneven tread wear

- embedded debris

- proper inflation

Correct air pressure directly impacts handling, braking, and fuel efficiency. Under-inflated tires increase stopping distances and stress suspension components.

Step 3: Brake Inspection

Short-haul trucks are helpless without a braking system. It is crucial to conduct daily brake inspections.

Warning signs to check for:

- unusual sounds

- delayed response

- uneven braking feel

- air pressure loss

Brake inspections are a core part of daily routine maintenance, especially in stop-heavy urban routes.

Brake problems do not pop up suddenly. Daily checks allow you to see the changes developing before safety margins run out.

Step 4: Fluid Check (Core Systems)

Fluid systems are responsible for many critical tasks in a semi truck. A quick fluid check is the way to prevent overheating, friction damage, and hydraulic failures.

The fluids that must be checked include:

- engine oil

- coolant

- brake fluid

- power steering fluid

This step supports preventative maintenance by identifying early system imbalance before it affects drivability.

Daily fluid-checking is one of the essential maintenance practices, especially in those vehicles that are subjected to multiple daily duty cycles.

Step 5: Engine Check at Startup

Upon getting inside the cab, the engine makes its virtual speech. Just as you listen to music before driving.

Engine check focuses on:

- strange sounds

- rough idling

- warning lights

- delayed response

This engine check helps detect early operational issues before the truck enters traffic.

Lights displayed on the dashboard should not be neglected when doing a pre-shift inspection. They are there to give earlier indications of whether something is going wrong with the system.

Step 6: Electrical System and Lighting

Short-haul routes are typically covered in the early hours, evenings, and often run inside warehouses. Visibility and signaling are mandatory.

Electrical system check:

- headlights and taillights

- turn signals

- brake lights

- dashboard indicators

Vibrational damage and the cycles of frequent usage — which are both commonly found in the short-haul operation — usually contribute to any electrical problems.

Step 7: Cab Safety and Equipment Maintenance

In the cab, make sure that the safety and operational equipment is in readiness.

Equipment checks in a cab include:

- seatbelt condition

- horn functionality

- windshield and wipers

- presence of emergency equipment

Regular equipment maintenance in the cab helps the drivers to focus on, comply with, and organize their work.

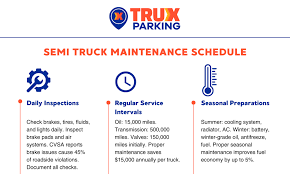

Daily Short-Haul Maintenance Checklist (Summary Table)

| Area | Inspection Focus | Purpose |

| Tires | Pressure, wear, damage | Stability and braking |

| Brakes | Response, air pressure | Safety control |

| Fluids | Levels, leaks | Engine protection |

| Engine | Noise, warnings | Early failure detection |

| Electrical | Lights, signals | Visibility and compliance |

| Cab | Safety equipment | Driver readiness |

Maintenance Logs and Checklist Templates

Consistency is more important than perfection. By using checklist templates and a maintenance log, you can turn daily inspections into a reliable process.

Logging the daily maintenance activity has a variety of benefits:

- creates inspection discipline

- supports service scheduling

- protects drivers in compliance reviews

- identifies recurring issues

A documented routine maintenance process is always more effective than relying on memory alone.

Preventative Maintenance Begins With Discipline

Daily short-haul inspection is the outermost line of truck maintenance. It is not just the mechanic’s duty — it starts with the driver.

Drivers who follow a structured service checklist:

- reduce breakdown risk

- improve vehicle lifespan

- maintain predictable schedules

- protect themselves legally and professionally

Preventative maintenance becomes effective only when it is applied consistently, shift after shift.

Conclusion: Short-Haul Reliability Is Built Daily

Short-haul trucking values consistency. A couple of minutes spent on daily maintenance before shift and a structured safety check save hours later on due to breakdowns, delays, and safety incidences.

This checklist does not mean adding work but rather eliminating uncertainty. When regular maintenance becomes your habit, and your truck is predictable, your shift is consequently safer. Operational readiness is not a random event. It gets built with every inspection undertaken.

Over time, these small, repeatable actions shape professional discipline and confidence behind the wheel. A driver who starts every shift with the same inspection routine and safety check reduces uncertainty, improves communication with maintenance teams, and builds trust in the vehicle’s condition. In short-haul operations, reliability is not accidental — it is reinforced daily through attention, consistency, and responsibility.

FAQ

What is the normal time span for a daily short-haul maintenance check?

To realize a complete daily short-haul maintenance check, it is necessary to spend approximately half an hour performing all required checks, although normal duration is usually between 10 and 20 minutes. The objective here is not to perform repairs, but to first of all check that the specific components are functioning normally and secondly to spot potential problems beforehand so that the shift can begin without issues.

Is the daily maintenance of short-haul trucks coupled with zero defects?

Indeed, it is a must. This is because these trucks perform frequent braking, engine restarts, and stop-and-go traffic resulting in 10% more wear and tear compared to their larger long-haul companions. Daily inspections of these vehicles are therefore fundamental and no longer a matter of choice.

What is the most frequently occurring fault on before shift operations?

Common issues are low air pressure in tires, minor fluid leaks, early brake wear, and dashboard warning lights. Most of these problems are small but if not treated in time, these may quickly spiral into bigger problems.

Are daily inspections enough or do they need to be complemented by proper maintenance services?

No, not all the time, of course. Daily inspections are clearly necessary in order to ensure meaningful gains in the service life of the equipment, but daily inspections do not take the place of the regular scheduled services needed on specified components. Regular inspections mitigate the symptoms of wear, while regular servicing entails adjusting or replacing certain components as required.

Should truck drivers report small technical defects even if they know the vehicle can run without them?

Yes. Small problems such as tires that are low on pressure or minor fluid leaks normally indicate that something is wearing out. It is good to signal these parts early before they become more troublesome or lead to mechanical breakdowns, delay, or safety risks.

What do maintenance logs drivers help with?

The maintenance logs not just provide proof of maintenance discipline but also include and respect compliance requirements, plus help in the detection of recurring issues. Also, they help the drivers with the official documentation required that the proper inspections were done by showing that they are performed prior to every shift.

What can be the consequences for skipping a daily inspection?

Skipping a daily inspection could lead to worn-out machinery, unsafe working environment, and increase in the transportation of goods. In short-haul operations, such as encountered during rush hours, regular inspections are even more vital otherwise mistakes are made.