The approach to maintenance is not merely a choice of technology for small trucking businesses, it is, in fact, a direct means of achieving profit. Breakdown repair or predictive maintenance, which is the best choice often determines not only your yearly maintenance costs but also your downtime exposure, your assets’ lifespan, and consequently the long-term financial stability of the company.

Most small trucking companies are still using the traditional reactive repairs which mean they only repair equipment after it has failed. This may be seen as cheap but the hidden costs almost always outweigh the perceived savings. Alternatively, predictive maintenance works to reduce unintentional breakdowns by working ahead, with data, and discipline.

To accurately gauge which route brings better returns on investment, a definite cost analysis that is reflective of conditions in the trucking business has to be undertaken.

What Is Breakdown Repair in Trucking

Breakdown repair is a form of reactive maintenance. The repairs are made only when a component malfunctions and is, in fact, commonly during the operation. In trucking, this behavior usually means roadside calls, emergency repairs, and unplanned downtime.

Key Points of Focusing on Breakdown Repair

The repairing process is initiated by the failure of the component

Heavy reliance on emergency repairs

Minimal upfront planning

High exposure to downtime costs

Initially, one would have thought that breakdown repair would be the least expensive option simply because maintenance spending would be postponed. Yet, the fact that exceptional repairs are practically always subject to high-hiking labor rates, the unavailability of parts, plus secondary costs such as missed loads, detention penalties and rescheduling is decisive.

For the small firms that work under the tightest margins, just a single unexpected breakdown can lead to the disruption of cash flow for a week.

Corrective maintenance of a vehicle.

The True Expense of Reactive Repairs

The real cost of reactive repairs transcends many aspects. When there is a malfunction, the breakdown makes the truck less efficient, leading to losses that exceed the repair cost.

Costs Uncovered by Breakdown Repair

Unplanned downtime reducing revenue-generating miles

Emergency towing and labor premiums

Shortened equipment lifespan due to cascading failures

Higher annual maintenance costs over time

“Unplanned sensor failure today can lead to a limiting engine tomorrow. A cooling issue left unchecked can escalate into catastrophic engine damage. Reactive repairs tend to address symptoms instead of root cause, increasing the probability of repeat failures.”

What is Predictive Maintenance in Trucking?

Predictive vehicle maintenance.

Predictive maintenance is a planned strategy that utilizes condition monitoring, inspection trends, and performance indicators to schedule repairs before failures occur.

Instead of relying on breakdowns, parts are serviced depending on wear patterns, usage intensity, and early warning signs.

Predictive Maintenance Idioms

Scheduled repairs based on current condition

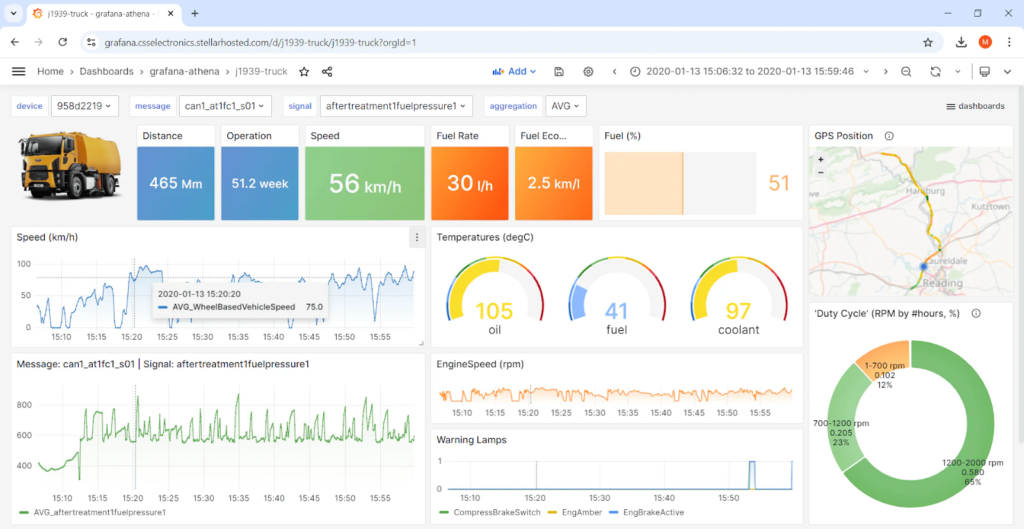

Oil and fluid analysis

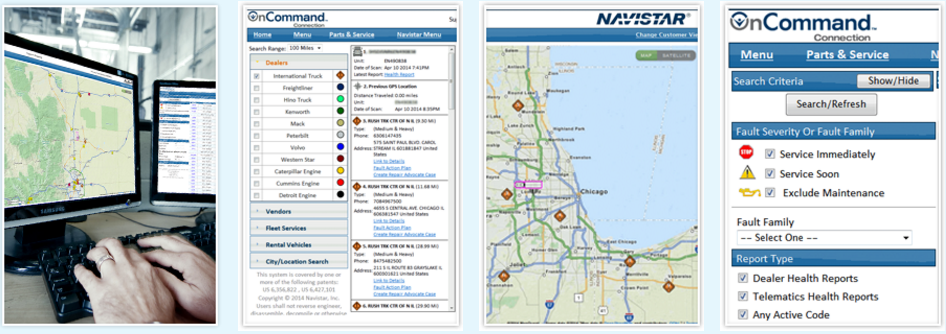

Monitoring fault codes and performance trends

Structured inspection records

Planned parts replacement

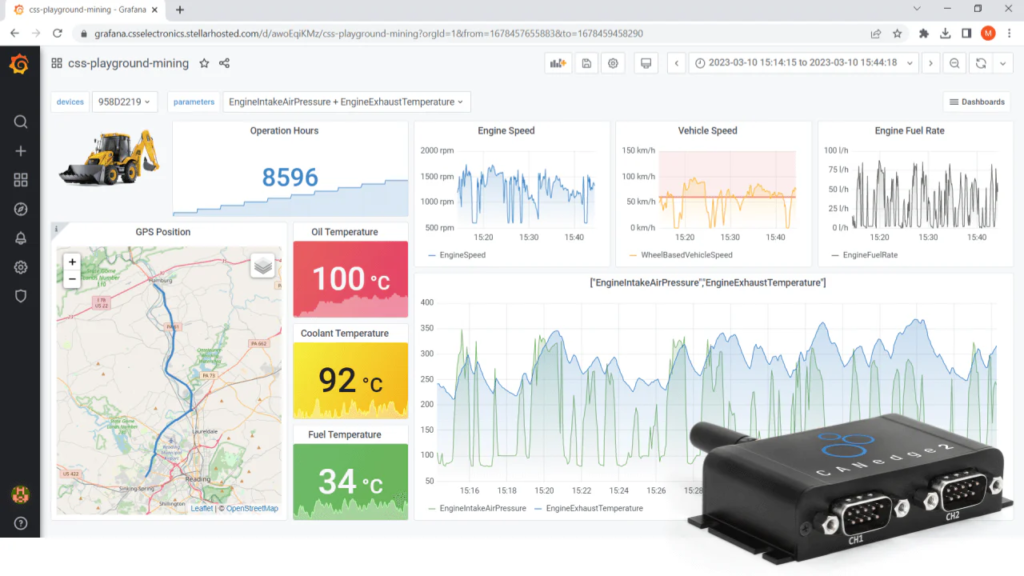

It does not require an enterprise-level software for the predictions of the trucking operation. A basic telematics site, disciplined inspections, and constant documentation can remarkably bring down the number of breakdowns.

Cost Analysis: Predictive vs. Reactive Maintenance

One of the main differences in the two methods is not just related to the costs, but also the predictability of costs.

| Cost Factor | Breakdown Repair | Predictive Maintenance |

| Repair timing | After failure | Before failure |

| Emergency repairs | Frequent | Minimal |

| Downtime costs | High and unpredictable | Low and planned |

| Annual maintenance costs | Volatile | Stable |

| Equipment lifespan | Shortened | Extended |

| Budget control | Poor | Strong |

Predictive maintenance, in contrast, transfers costs from irregular failures to manageable, scheduled repairs. Although the initial maintenance outlays may turn higher a little, the total costs will be reduced due to fewer big failures and shorter downtime.

Downtime Expenses: The Stealth Profits Reduction

The fact of the matter is that for small trucking companies, downtime often costs far more than the repair itself.

Every single hour off the highway knocks out:

- Lost freight revenue

- Missed delivery windows

- Customer dissatisfaction

- Dispatcher inefficiency

Unplanned downtime commences and multiplies. A single breakdown could eradicate the profit that was to be received from a couple of loads. Predictive maintenance specifically targets the faults leading to trucks becoming out of service, thus, keeps them on the road when the most needed.

Equipment Lifespan and Asset Value

Establishing repair-heavy routines brings about wear and tear. System components tending to fail due to stress and, in many cases, the additional damage to the other systems.

Predictive maintenance:

- The lifespan of machines is increased

- Resale and trade-in value are preserved

- Catastrophic failures are lessened

From a small business perspective, extending asset life by even one additional year significantly improves return on investment and reduces capital pressure.

Predictive Maintenance and Small Business Efficiency Gains

Predictive maintenance is beyond only repairs; it is also about improving operation efficiency.

Efficiency Gains Include

Less emergency service interruptions

More consistent dispatch planning

Better asset annual utilization

Lower stress on drivers and maintenance staff

Planned repairs are scheduled around loads, home time, and shop availability. The association of this planning makes productivity increase and disturbance decrease.

Annual Maintenance Costs: Stability vs. Volatility

Increased costs due to harm prevention repairs are naturally the outcome of a breakdown at the time. There are some months when it would seem like there are little costs, but others show that a lot of money was spent.

Predictive maintenance results in:

- More accurate annual maintenance forecasting

- Lower financial shocks

- Predictable cash flow

| Scenario | Breakdown Repair | Predictive Maintenance |

| Minor repairs | Low | Moderate |

| Major failures | High | Rare |

| Emergency costs | Frequent | Minimal |

| Total annual cost | Higher | Lower |

The very essence of predictability becomes a financial benefit for small businesses.

Emergency Repairs vs. Planned Repairs

Emergency repairs have their own inherent disadvantages:

- Limited shop choices

- Higher labor rates

- Poor parts availability

- Increased secondary damage risk

Planned repairs give you the opportunity to:

- Negotiate pricing

- Choose the service provider

- Do diagnostics

- Conduct better quality control

Planned repairs always result in lower costs and better quality.

Which Is the More Economical Approach for Small Trucking Businesses?

A complete cycle assessment shows that predictive maintenance is a better way to go compared to breakdown repair.

Main benefits for Predictive Maintenance

Lower long-term costs

Reduced emergency exposure

Higher asset reliability

Boosting efficiency across operations

Basing on the steal a cog wheel rule of thumb, predictive maintenance would fit here, as it greatly reduces unplanned downtime and critical component failures making it more cost-efficient in the long run.

Final Verdict: Prevention Makes Profit

The profitability of small trucking businesses is not through skipping maintenance but rather through controlling that.

Transforming maintenance from a financial shock into a planned operational expense is made possible through predictive maintenance. Reducing dependency on breakdown repairs, cutting emergency costs, and extending equipment lifespan, small shops can ensure long-term savings and operational viability.

The strategy most likely to bring profits in truck driving is not responding quickly to failures but it is to preempt them before they happen.

Additional Analysis: Maintenance Strategy as a Driver of Small Business Profitability

For owner-operators and small fleets, small business profitability is shaped by dozens of operational decisions, but maintenance strategy remains one of the most decisive. Predictive maintenance directly contributes to repair savings by shifting spending from crisis response to controlled interventions. Instead of reacting to failures with high invoices, businesses gain visibility into component health and plan interventions at the most economical moment.

Over time, this approach delivers consistent efficiency gains. Trucks spend more days on the road, dispatchers experience fewer disruptions, and maintenance windows are aligned with revenue cycles rather than emergencies. When equipment performance is monitored continuously, each asset contributes more value asset annually, improving utilization without increasing fleet size.

Planned repairs also change the quality of decisions. Rather than approving fixes under pressure, operators can compare pricing, choose trusted vendors, and confirm diagnostics. This makes maintenance more cost-effective, not because repairs disappear, but because they happen under controlled conditions. The result is measurable breakdown reduction and far fewer moments where a truck is sidelined unexpectedly.

From a financial standpoint, predictive maintenance keeps minimal emergency costs on the balance sheet. Emergency repairs tend to produce higher costs not only in labor but also in lost revenue and operational chaos. Eliminating those spikes stabilizes cash flow and protects margins, which is critical for small trucking businesses operating with limited reserves.

Ultimately, predictive maintenance is not about perfection — it is about control. It allows small operators to protect uptime, reduce exposure to catastrophic failures, and turn maintenance into a strategic tool rather than a recurring crisis.

FAQ: Breakdown Repair vs. Predictive Maintenance in Trucking

Is predictive maintenance really worth it for a small trucking business?

Yes, predictive maintenance is most of the time more chipper for small trucking companies than merely to the breakdown repair. While it may temporarily required regular inspections, monitoring tools, or basic telematics, these costs are predictable and controllable. On the other hand, breakdown repair pushes small companies to the brink of facing unexpected high costs, emergency labor rates, and lost income due to downtime. Eventually, predictive maintenance cuts down the total maintenance cost and ensures a steady cash flow.

Why do breakdown repairs usually end up costing more than expected?

Breakdown repairs are hardly ever about just the faulty part. One failure incident leading to a whole lot longer consequences like secondary damage, towing charges, missed shipments, and delivery penalties. Emergency repairs not only raise the price but usually limit shops’ choices as well which creates a monopolizing effect. The differences in costs are such that breakdown repairs turn out to be considerably more expensive than they seem initially, particularly for the small fleets which experience the least flexibility in their operations.

Can predictive maintenance work without expensive technology?

Yes. Predictive maintenance does not require expensive enterprise-level systems. Many small operators use structured inspection routines, fault code monitoring, oil analysis, and maintenance logs to complete this. Consistency as well as documentation are more critical than advanced software. Even condition-based planning used in the simplest way can achieve a significant reduction in the unplanned downtime.

How does predictive maintenance affect the lifespan of the equipment?

Predictive maintenance allows equipment to have an extended lifecycle by dealing with the wear and tear before damaging it significantly by major failures. The components are under the right conditions during the service which reduces the stress on the related systems. Thus, not only do the long-term repair costs go down but the resale value also remains intact while the assets are postponed from being replaced by the costly ones.

Does predictive maintenance eliminate emergency repairs completely?

There is no maintenance strategy that can completely avoid emergencies but predictive maintenance at least minimizes them. If/when the failures strike, they tend to be less severe because earlier signs were looked into. This makes emergency repairs rare (not routine) rather than.

Which maintenance strategy is better for the long run in terms of profitability?

For the small trucking businesses, always the predictive maintenance proves over and again to be the cheaper way to run it. It cuts down on the possibility of an emergency, which in turn improves planning, thereby enhancing uptime, and alters maintenance from a painful shock to a manageable operational expense. Over time, this pathway to profitability supports sustainable development far better than in the case of just responding to the breakdown.