Beginner drivers often view maintenance as something detached and complicated that is done only by mechanics and not by the ones actually driving the vehicle. Quite the opposite, this thought pattern gets you in trouble in truck driving. The great weight of the vehicle, continuous operating hours, the trucker’s need for maintenance makes it clear that truck driving is not just a job but a commitment to professional responsibility.

This perspective explains why basic maintenance should be treated as a daily responsibility rather than an occasional task.

Becoming acquainted with the working of a car does not begin with a wrench, but with an orientation to how the vehicle finds its stability when operating under daily driving conditions. This approach defines the foundation of beginner car maintenance in professional truck driving.

Most serious machinery breakages are unexpected. They begin their operation with hidden changes that the driver can ignore without thinking. The incredible step to getting solace from such losses is becoming aware that consistent research and development on the vehicle is good for both the road and safety.

Recognizing early signs of breakdowns allows drivers to intervene before those hidden changes evolve into operational failures.

This short guide is meant for beginners wanting to know a bit more about how to care for their vehicles and focuses on sensors for serious car problems, mechanics on how to treat early alerts and maintenance making the vehicle cost-effective. It emphasizes vehicle maintenance as a preventive process rather than a reactive one.

The Importance of Basic Maintenance in Truck Driving

The trucks are engineered to take a beating, but this does not mean that no wear will occur. Suffering from exposure such as the long-distance traction-damaging component are idling, weather, and payloads, which make them stress and eat faster. The ignorance of minor problems causes them to transfer to other systems.

Understanding common car problems at an early stage helps drivers prevent breakdowns and maintain operational stability.

Handy maintenance makes it possible for the trucks to be in good shape by drivers verifying their operations early on and cleaning or changing defective parts that would normally break down. This reflects the core idea of essential maintenance in truck driving.

Basic maintenance is not only about saving the vehicle from breakdowns. It teaches you to be observant. Doing so, the drivers will get to know whether their vehicle is functioning as it should is whether something is changing without them realizing it.

On the business side of maintenance, the mechanic sees this as a good record of safety, compliance, scheduling, and reliability. Turning over preemptive maintenance helps the truck and the driver’s load equally and supports long-term car breakdown prevention.

Careful Attention Every Day Comes Before Mechanical Knowledge

Most of the new divers think that it is the tools that maintain the car. The first step of maintenance is observing things. When a driver hears something new, feels something different, or sees a change in performance he/she already does effective maintenance.

This mindset aligns with simple car maintenance practices that rely on consistency rather than technical complexity.

Making regular checks does not require you to be a mechanic; you only need to have your eyes and ears open. These daily observations form the basis of routine maintenance.

Awareness in the daily sense means checking visuals, listening to the engine when starting up, and examining the feeling of the truck under a specific load. These habits need little time but can reveal issues several days or weeks before a breakdown actually happens.

How to AVOID the Most Common Truck Breakdowns (Inspect these 6 Truck Parts Before Hitting the Road)

Probing for potential issues is not just for survival; it is for good practice. The main areas of attention include:

- liquid presence visible beneath the vehicle

- changes in the startup sound

- dashboard signals

- response speed while accelerating and braking

Observations like these will form the basal of broken car parts yet the driver wont be needing any mechanics skills.

Concentrating Beginner Maintenance Points

| Area | What to Observe | Why It Matters |

| Engine oil | color, level, warning light | prevents engine wear |

| Tires | Pressure, visible damage | Affects safety and fuel use |

| Brakes | Noise, response time | Direct safety system |

| Fluids | Levels and leaks | Prevents overheating and failure |

| Battery | Startup behavior | Avoids no-start situations |

Engine Oil: Signals Not to Be Overlooked

The habit of regularly checking the car engine oil is one of the most practical skills a beginner driver can have. The oil is the liquid that cools, lubricates, and protects the components of a car engine. High levels of friction can be caused by oil that is of poor quality or if the oil level is low.

Learning how to check engine oil correctly is a fundamental part of automotive maintenance.

Consistent oil checks are the easiest way, and one of the best ways, to maintain the car and are very beneficial.

Most problems related to the oil gradually appear. Drivers may observe louder engine operation, engine noises during acceleration, sluggish response, or some of the dashboard alerts. These are early signals in the sense that they’re not just background noise.

Ignoring oil issues might lead to engine damage if they are buy the maintenance products only. Oil checks are a straightforward way to maintain your vehicles and prevent breakdowns.

Tires, Pressure, and Fuel Efficiency

Tires are the part of the vehicle that influences more than just the traction. Through tire pressure checks, drivers are able to impact braking distance, handling stability, and fuel consumption as well.

Knowing when and how to check tire pressure helps avoid decreased fuel efficiency and uneven mechanical stress.

Improper tire pressure increases rolling resistance which mostly means lower fuel efficiency. This problem leads to inefficiency over time and, in turn, causes stress on other systems.

Uneven tire wear may also indicate poor alignment or suspension problems. The visible state of the tires is only a part of the story; firstly, the car mechanics are the ones who see the bigger picture.

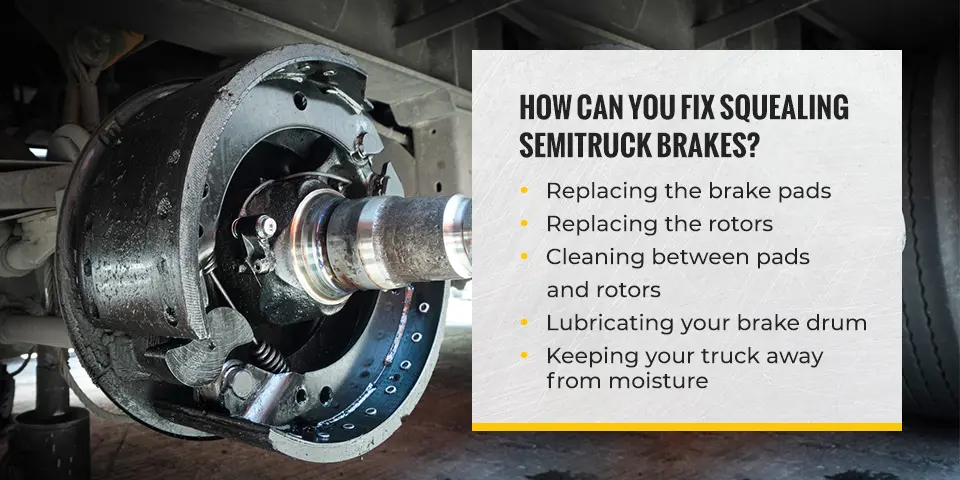

Braking Systems: Sounds are Messages

Brake systems are some of the safety systems that give almost all the warning signs before they actualize their problems. Squealing brakes, grinding noises, and delayed stopping are some simple visual indicators of a problem with braking.

Being able to identify squealing brakes early allows drivers to inspect brake pads before serious damage occurs.

It is essential for you to learn how to look for the pads by yourself, and how to respond to the abnormal sounds that brakes make.

Brake warning signs should be invariably given the first priority due to their time sensitivity. The change in the brake even sometimes small affects especially the load or the traffic so can it.

Drivers who pay attention to the braking behavior are at the same time are protecting themselves and the surrounding traffic.

Fluid Levels and System Healthy

Apart from the oil the car also parts do operate independently and do not need attention. The coolant removes excess heat, the brake fluid boosts stopping power, and the transmission fluid insulates the drive shaft from premature wear.

Monitoring fluid levels is one of the simplest and most effective ways to prevent mechanical escalation.

Fluid check-ups are still one of the best practices to stop overheating or hydraulic failure that are some of the common breakdown causes.

Fluid-related problems such as low or contaminated fluids do not replace the worn part immediately but they do it faster. Checking on the fluid is an especially effective maintenance habit that reduces the risk of a bigger issue down the line.

Common Warning Signs and Their Meaning

| Warning Sign | Possible Cause | Recommended Action |

| Engine noises | Oil or mechanical wear | Inspect oil and schedule check |

| Dashboard warnings | Sensor or system issue | Diagnose promptly |

| Reduced braking response | Pad or fluid issue | Immediate inspection |

| Fuel efficiency drop | Tire or engine issue | Check pressure and filters |

| Electrical glitches | Battery or wiring | Battery inspection |

Battery Health: Quiet but Critical

The car battery seldom brings attention unless it is dead. The lifespan of a battery is cut short if the vehicle is used frequently on cold starts, short journeys and with electrical loads.

Battery failure is one of the most overlooked common car problems in daily truck operations.

The signs of the battery problems come with time such as slower cranking, dimmed lights, or dashboard warnings that are often present before total failure. These patterns in a prior event of battery problems make them the best candidates for treatment.

Battery tests are simple and inexpensive and save you a lot of time and in the end, they will help you to take care of the car.

Routine Maintenance vs. Reactive Repairs

Truck Maintenance Like the Pros (for All Truck Sizes)

What makes the difference between the two is the control. When the preventive checks are done on schedule and calm conditions existing, those checks are not reactive repairs. Reactive repairs take place at unexpected times, sometimes on the roadside.

Routine maintenance reduces uncertainty and transforms vehicle reliability into a managed process.

The routine inspections are like a periodic checkup for the car that reduces uncertainty.

Beginners who are oriented toward preventive habits reduce their stress, cost, and the disruption of their schedule. Maintaining consistency in maintenance changes the reliability from chance which is a process.

Preventive vs Reactive Approach

| Aspect | Preventive Maintenance | Reactive Repair |

| Timing | Planned | Unexpected |

| Cost | Predictable | Higher |

| Stress | Low | High |

| Safety impact | Controlled | Elevated risk |

| Downtime | Minimal | Extended |

DIY Maintenance: Knowing What You Can Do

DIY car maintenance for beginners is about safe boundaries. Visual inspections, fluid checks, tire pressure monitoring, and listening for abnormal sounds fall well within driver responsibility.

These actions represent the practical core of beginner vehicle maintenance.

Attempting complex repairs without training can cause harm. Effective maintenance means knowing when to observe, when to report, and when to escalate.

Final Thoughts: Maintenance Is Awareness, Not Expertise

Beginner maintenance is not about mechanical mastery. It is about awareness, consistency, and early response. Most breakdowns announce themselves quietly — through sounds, lights, or subtle changes. Drivers who develop observation habits, respect warning signs, and maintain routine checks reduce risk and extend vehicle reliability.

Practical car care tips start with a simple car checkup mindset, where daily car checkups become a normal part of the driving routine rather than a special task.

In truck driving, maintenance awareness is not an extra skill. It is part of professional driving discipline.