The expenses from broken equipment. Truck drivers and fleet owners know all about this. Out of the blue break downs, insurance claims that were not covered, or even a mistake in reading the maintenance contract can turn the regular service into a huge cost for the drivers to pay. Drivers often have an idea that extended warranty is a sure way to be protected until they find out which list of things is not covered, some terms, and conditions, and the procedures that were expected.

The best way to avoid unreasonable expenditures for fixes and repairing fraud is to know the mechanics of service plans and warranties. This article, which is written from the standpoint of a truck driver, outlines the most frequently asked questions about service plans and warranties and discusses the ways to avoid getting into financial troubles beforehand.

Warranties and Service Contracts in Trucking: Why It Matters?

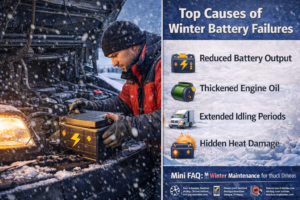

Truck machinery has to embrace extremely rough conditions such as very tight schedules, long-haul trucks with lots of weight, and intermittent hot and cold temperatures, among others. For that reason, it is common to have maintenance and repair expenses. Nevertheless, what is preventable is spending for repairs that should have been under warranty.

A service contract or product warranty stipulates:

- Covered parts

- Approval conditions for repair

- Job assignment / General who can do the work

- Claim filing procedures

If the driver misunderands any point such as the above, he may incur costs instead of the supplier as per the agreement.

The product warranty and the extended warranty are not the same

A product warranty, which is basically a limited warranty, comes with the truck or part and mostly includes the defects exercised during the manufacturing period, which is time or mileage-dependent. Conversely, the extended warranty is a separate service plan that can be purchased for a limited period and is not included in the original one.

Important differences which matter to the truck drivers are:

- Limited warranties usually do not cover wear and tear items

- Extended warranties differ widely in terms of the level of coverage

- Some of the extended warranties restrict repair centers

- Third-party providers may have stricter claims processes

It is often hard for drivers to come up with coverage details, which they frequently presuppose to be there when in fact such coverage does not.

The Role of Service Centers that are Authorized

Improper repair location is one of the most common causes of warranty claims being rejected. Most warranties specifically require that repairs are done by an authorized service provider.

Using a private shop can seem adequate in terms of cost in some cases, but it can practically:

- Void possible warranty coverage

- Obstruct future claims

- Displace total repair costs on the driver

Prior to the approval of an appliance repair, engine work, or component replacement make sure whether the shop is qualified as the warranty terms and conditions imply.

Understanding Details of Coverage Prior to a Breakdown

The coverage details are the areas where the most costly repairs are hidden. Truck drivers need to seek the following information:

- What is covered and what is not

- If it is diagnostic based that they will be reimbursed

- The labor rate caps

- Deductibles and co-pays

- Mileage or usage limits

A faulty product may even be outside warranty protection if exclusions are applied. Thus, it is essential for them to know this thing beforehand in order to budget properly and avoid peak when time is short.

Common Warranty Pitfalls and Their Financial Impact on Truck Drivers

| Situation | What Drivers Often Assume | What Actually Happens | Financial Outcome |

| Repair done outside authorized service | Any certified mechanic is acceptable | Warranty requires an authorized service center | Full repair becomes out-of-pocket |

| Diagnostic work before approval | Diagnostics are automatically reimbursed | Diagnostics may be excluded or capped | Driver pays diagnostic costs |

| Wear-related component failure | Part failure should be covered | Wear and tear is excluded under limited warranty | Claim denied, repair not covered |

| Verbal approval from service shop | Shop confirmation equals warranty approval | Only warranty administrator approval is valid | Repair cost shifted to driver |

| Missed maintenance interval | Small delay does not affect coverage | Warranty requires strict maintenance compliance | Warranty voided for related failure |

| Emergency repair authorization | Urgency justifies immediate repair | Lack of pre-approval invalidates claim | Expensive fixes paid by driver |

Repair Estimates and Repair Fraud Risks

Not every costly repair job is legitimate. Repair fraud usually is:

- Inflated repair prices

- Totally unnecessary part changes

- Warranty coverage does not apply unless verified claims

To safeguard your interests you can:

- Request a written repair estimate

- Authorized service providers should be compared across the board for similar estimates

- The company should return the parts in question or document usage accordingly

- The warranty administrator should be contacted directly for verification of claims stated by the service provider

Dependable repair decisions should be based on documents only and not on the pressure of the time in situation.A reliable repair in trucking is defined not by speed or promises, but by verified documentation, authorized procedures, and warranty-aligned execution.

Consumer Rights and the Claims Process

Truck drivers have their consumer rights even if it is a commercial environment. These are:

- The right to be told in which words the warranty exists

- The right to question claims that have been rejected

- The right to have a clearly explained claims process

If a claim is declined, the individual may request:

- The right clause causing the denial

- Document evidence to back it up

- The steps to take to appeal

No warranty claim should be unfairly denied as long as proper written records are provided about maintenance and service.

Maintenance Plans as Cost Protection

One of the most effective weapons against the warranty claims is the presence of a documented maintenance plan. This is mainly through preventive maintenance by:

- Ensuring the warranty remains valid

- Reducing the risk of failure

- Strengthening the claims approval

- Taking the future repair costs down

Of course, breaking services or maintenance not documented are the common causes of denied coverage even if the fault would normally qualify the coverage.

Service Plans and Long-Term Cost Control

A well-structured service plan is, in fact, a coherent tool with maintenance schedules, warranty requirements, and operational consumption streamlined. This kind of therapeutic approach for trucks owned and operated will assure:

- The stabilization of repair expenses

- Reduced downtime

- Avoidance of sudden expensive repairs

- Improved resale value

The main aim is not avoiding repairs altogether but controlling the timing and method of repairs incurred.

How Drivers Make Mistakes That Result or Lead to Expensive Repairs

Most of the expensive repairs have a common sequence of events:

- Warranty terms are not well comprehended

- Repairs carried out beyond authorized personnel

- Maintenance records are not complete

- Claims are filed improperly or probably delayed

Each step observed above increases foundations of outdoing the amount.

Practical Checklist Before Any Major Repair

Before key operations are approved let’s:

- Have a look at the warranty and service contract terms

- Verify the list of eligible authorized service providers

- Request the itemized repair estimates

- Let the warranty provider be contacted before the repairs start

- Have a full documentation of everything

In a few minutes, if you carry out these steps, you can save thousands of dollars.

Additional Practical Guidance: The Path from Repairs to Out-of-Pocket Expenditures

The most underrated threat to trucking maintenance is the slow transition from repair fully covered by the insurer to totally out-of-pocket responsibility. This change seldom happens at once. More frequently, it is caused by a causal circle of small mistakes: a lack of documentation, unperformed service intervals, or miscommunication with customer service agents. Each of these weak areas entraps the driver into the costly fixes that he/she thought would never be his/her responsibility to pay.

When a truck breaks down in a situation where there is little time to spare, a particular pattern can be seen. The truck has to be stationary, the deadlines are inside danger, and the driver gives the go-ahead for repairs, the confirmation of the covered service being pending. Thus, the urgency supersedes the verification, and costs intended to be shared or absorbed just move to the driver’s side independently.

Where Repair Fraud Typically Enters the Picture

Repair fraud does not always look like intentional deception. In many cases, they give the impression of:

- Overtly exaggerated labor hours

- Replacing whole assemblies rather than just the ruptured components

- Obscure justifications of the warranty non-coverage

These claims remain unattested until there is the signature of the warranty administrator. Drivers who base their decisions solely on the verbal confirmations often find out later that the fix was never included, that is, they are bearing all the costs.

Customer Service as a Cost-Control Tool

The warranty customer service departments are resorted by many drivers as tactical units. These departments are not for the filling-in of the claims after repairs only but should be touched before the authorization is given. The advanced dialogue can:

- Verify a hurting machine is to be replaced

- Give the names of the service authorized to carry out repairs

- Clarify diagnostic reimbursement rules

- Prevent unauthorized work

Drivers who share client service both equitably as well as a strategic partner instead of a last resort tend to diminish their financial exposure remarkably.

Preventative Maintenance and Financial Predictability

The most effective both against repair fraud and denied claims is the proper documentation preventive maintenance. Preventative measures do not only decrease the number of accidents but also create a way of proving compliance and retaining coverage.

Regular maintenance logs establish:

- The service intervals

- Proper operating procedures

- No failures occurred due to negligence

How Expensive Fixes Escalate Over Time

There are many costly fixes that initially seem to be only minor ones either of the two – hoarded problems or wrongly diagnosed. A small leak might lead to the whole assembly having to be replaced as it was neglected during the normal inspection.

Establishing a Repair Plan that Secures the Income

The secret of staying away from costly repairs is not avoiding maintenance; it is managing it strategically. The right tactics incorporate:

- Repair after verification of authorization

- Clear interaction with warranty personnel

- Choice of service organizations that are approved

- Neat documentation

- A long-drawn plan of maintenance

Final Thought

Trucking is a business where mechanical failure is a part of the deal. But financial failure is not a deal at all. The drivers who learn the interconnectedness of repair fraud, out-of-pocket exposure, and warranty limitations are better prepared to secure their income.

Conclusion: Knowledge Is the Best Protection

In driving trucks, high repair costs do not necessarily come as a result of mechanical weaknesses; no, in many cases are the result of lack of information. Through the clear understanding of service contracts, product warranties, coverage details, and the claims process, truck drivers are empowered to make informed decisions before prices go higher.

The combination of proactive maintenance, accountable repair practices, and organized documentation allows truck drivers to keep their income, to protect themselves against the fraud of repair and to ensure that the warranties are being use as they are supposed to not as the fine print side effects.